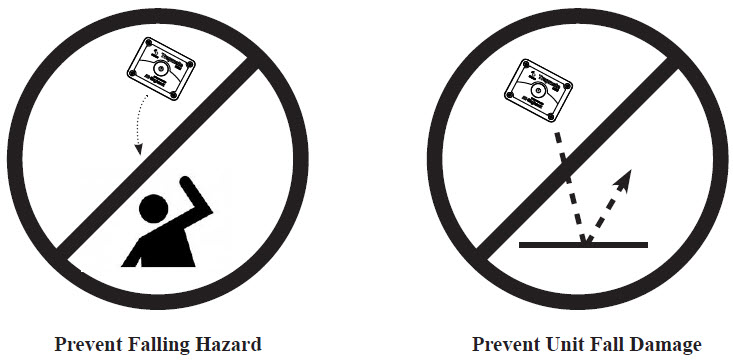

SAFETY AND USE RESTRICTIONS

DO NOT USE SKYHAWK MiniSensor :

- IN PLACE OF A LIFE SAFETY

- FOR MEDICAL

- IN A MANNER THAT VIOLATES ANY FEDERAL, STATE, LOCAL, ADMINISTRATIVE OR OTHER LAW, REGULATION, OR ORDINANCE, INCLUDING BUT NOT LIMITED TO GOVERNANCE OF CRIMINAL OR ILLEGAL ACTIVITY, DATA PRIVACY AND SECURITY, HEALTH AND SAFETY, ANIMAL WELFARE AND/OR WILDLIFE TRAPPING.

DO NOT ATTACH SKYHAWK miniSensor DIRECTLY TO A LIFE SAFETY OR MEDICAL MONITORING DEVICE.

DO NOT PLACE OR POSITION SKYHAWK MiniSensor WHERE IT COULD INTERFERE WITH SAFE OPERATION AND FUNCTIONALITY OF LIFE SAFETY, MEDICAL MONITORING OR OTHER EQUIPMENT.

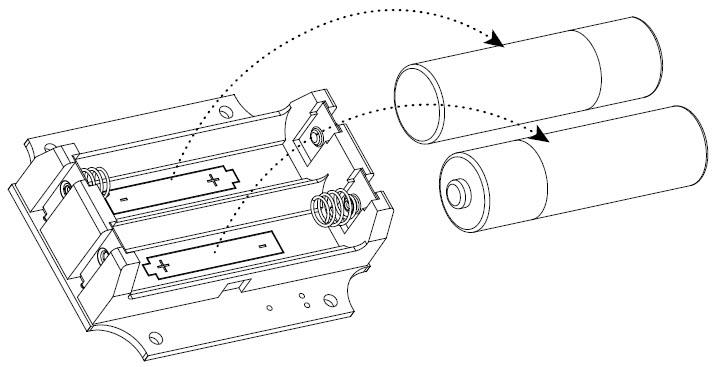

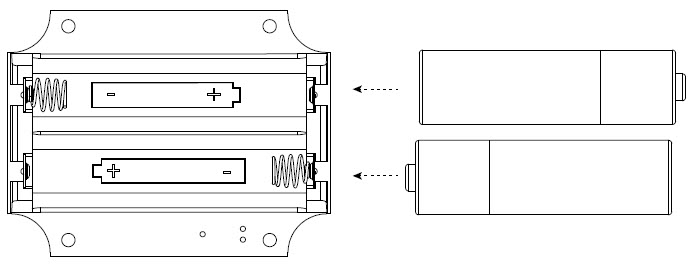

BATTERIES:

The Skyhawk MiniSensor uses hermetically sealed alkaline iron disulfide batteries. Under normal conditions of use, alkaline iron disulfide batteries are non-toxic and are not hazardous waste per the United States Resource Conservation and Recovery Act (RCRA) – 40 CFR Part 261 Subpart C. Dispose of in accordance with all applicable federal, state and local regulations.

WARNING: BATTERIES CAN EXPLODE OR LEAK AND CAUSE BURNS IF INSTALLED BACKWARDS, DISASSEMBLED, CHARGED, OR EXPOSED TO WATER, FIRE OR HIGH TEMPERATURE. EXPOSURE TO THE INGREDIENTS CONTAINED WITHIN OR THEIR COMBUSTION PRODUCTS COULD BE HARMFUL.

IMPORTANT NOTICE:

The Skyhawk MiniSensor uses a 3rd-party Wireless Service which uses radio technologies and is subject to transmission and service area limitations, which may include interruptions and dropped connections caused by atmospheric, topographical or environmental conditions, cell site availability, cellular network equipment or its instal- lation, governmental regulations, system limitations, maintenance or other conditions or activities affecting the operation of the Wireless Service. The Wireless Service and/or features may not be available in all areas. For more information, visit sky-hawk.com.

FCC AND COMPLIANCE

RADIO AND TELEVISION INTERFERENCE: This equipment has been tested and found to comply with the limits, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving

- Increase the separation between the equipment and the

- Connect the equipment into an outlet on a circuit different from that to which the receiver is

- Consult the dealer or an experienced radio/TV technician for

Changes and Modifications not expressly approved by the manufacturer or registrant of this equipment can void your authority to operate this equipment under Federal Communications Commissions rules.

IC ES 003 : This Class B digital apparatus complies with Canadian ICES-003 Cet appareil numérique de la classe B est conform e à la norme NMB-003 du Canada.

LIMITED WARRANTY ON SKYHAWK miniSensor

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY BY STATE, PROVINCE, OR JURISDICTION. THE LIMITED WARRANTY CAN ALSO BE FOUND ONLINE AT SKY-HAWK.COM/WARRANTY AND IN THE DOCUMENTATION WE PROVIDE WITH THE PRODUCT. WE WARRANT THAT DURING THE WARRANTY PERIOD, THE PRODUCT WILL BE FREE FROM DEFECTS IN MATERIALS AND WORKMANSHIP. WE LIMIT THE DURATION AND REMEDIES OF ALL IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE TO THE DURATION OF THIS EXPRESS LIMITED WARRANTY. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. OUR RESPONSIBILITY FOR DEFECTIVE GOODS IS LIMITED TO REPAIR OR REPLACEMENT AS DESCRIBED BELOW IN THIS WARRANTY STATEMENT.

WHO MAY USE THIS WARRANTY?

Pica Product Development, LLC located at address 4 Ash Street Extension, Derry, NH 03038 (“we”/ “our”) extend this limited warranty only to the consumer who originally purchased the Product (“you”/ “your”). It does not extend to any subsequent owner or other transferee of the Product.

WHAT DOES THIS WARRANTY COVER?

This limited warranty covers defects in materials and workmanship of the SKYHAWK MiniSensor (the “Product”) for the Warranty Period as defined below.

WHAT DOES THIS WARRANTY NOT COVER?

This limited warranty does not cover any damage due to: (a) transportation; (b) storage; (c) improper use; (d) failure to follow the Product instructions or to perform any preventive maintenance; (e) modifications; (f) unauthorized repair; (g) normal wear and tear; or (h) external causes such as accidents, abuse, or other actions or events beyond our reasonable control. IN THE EVENT THAT THE PRODUCT SERIAL NUMBER IS MISSING OR HAS BEEN ALTERED IN ANY WAY, THIS LIMITED WARRANTY IS VOID AND WITHOUT EFFECT AND PICA PRODUCT DEVELOPMENT, LLC SHALL HAVE NO LIABILITY WHATSOEVER FOR DEFECTS OF SUCH PRODUCT.

WHAT IS THE PERIOD OF COVERAGE?

This limited warranty starts on the date of your purchase and lasts for ONE (1) YEAR, or as long as the product is owned by the original purchase, whichever time period first occurs (the “Warranty Period”). The Warranty Period is not extended if we repair or replace the Product. We may change the availability of this limited warranty at our discretion, but any changes will not be retroactive.

WHAT ARE YOUR REMEDIES UNDER THIS WARRANTY?

With respect to any defective Product during the Warranty Period, we will, in our sole discretion repair or replace such Product (or the defective part) free of charge. We will also pay for shipping and handling fees to return the repaired or replacement Product to you.

HOW DO YOU OBTAIN WARRANTY SERVICE?

To obtain warranty service, you must call 1-800-760-3966 or E-mail our Customer Service Department at [email protected] or provide written notice to PICA Product Development, LLC of any defective part or conditions during the Warranty Period to obtain a Return Merchandise Authorization (“RMA”) number. No warranty service will be provided without an RMA number. You may, at our discretion, be required to return the Product or provide other proof of defect. When required to return the Product, you will be provided with shipping instructions and proof of purchase must accompany shipment. You are responsible for all shipping and handling charges in connection with performance of this limited warranty. For additional RMA process details go to skyhawk.ai/warranty.

LIMITATION OF LIABILITY

THE REMEDIES DESCRIBED ABOVE ARE YOUR SOLE AND EXCLUSIVE REMEDIES AND OUR ENTIRE LIABILITY FOR ANY BREACH OF THIS LIMITED WARRANTY. OUR LIABILITY SHALL UNDER NO CIRCUMSTANCES EXCEED THE ACTUAL AMOUNT PAID BY YOU FOR THE DEFECTIVE PRODUCT, NOR SHALL WE UNDER ANY CIRCUMSTANCES BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, SPECIAL OR PUNITIVE DAMAGES OR LOSSES TO ANY PERSON OR PROPERTY ARISING OUT OF THE USE OR INABILITY TO USE THE PRODUCT INCLUDING, BUT NOT LIMITED TO, PERSONAL INJURY, WRONGFUL DEATH, PROPERTY DAMAGE, LOSS OF DATA, LOSS OF REVENUE OR PROFITS, BUSINESS INJURY, BUSINESS INTERRUPTION OR ANY OTHER DIRECT OR INDIRECT DAMAGES, EVEN IF PICA PRODUCT DEVELOPMENT, LLC HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

THE TERMS OF THIS LIMITED WARRANTY WILL APPLY TO THE EXTENT PERMITTED BY APPLICABLE LAW. FOR A FULL DESCRIPTION OF YOUR LEGAL RIGHTS YOU SHOULD REFER TO THE LAWS APPLICABLE IN YOUR JURISDICTION.